Pilot centrifuges - Technology center

We provide rental of pilot centrifuges (inverting filter, peeling knife) to carry out tests both at the customer and at our plant.

The tests are critical to select the most suitable centrifuge for solids/liquid separation.

The evaluation of the test results, coupled with a specialized software dedicated to filtration and optimization of the solid/liquid separation process, allows us to guide the Customer in choosing the centrifuge model and size that suits the Customer’s needs and productive expectations.

Our service engineers and our process engineers will provide the customer with all the technical support required, for the installation of the pilot centrifuges and for the execution of the tests.

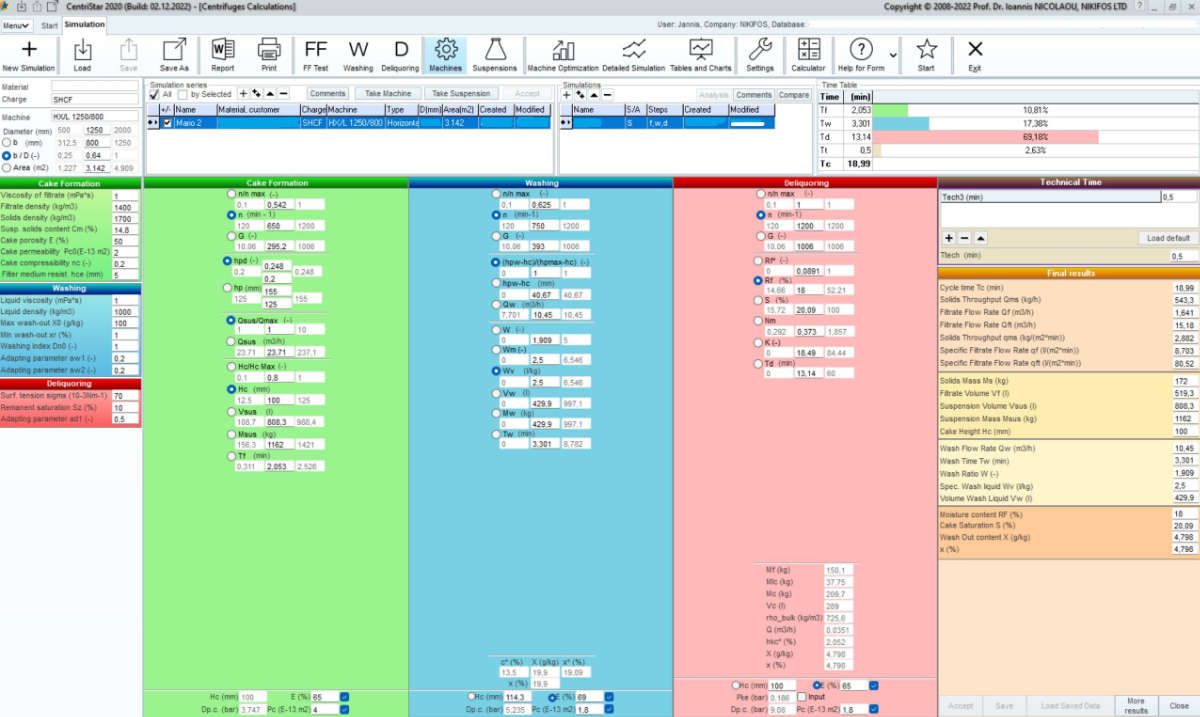

CENTRISTAR solid/liquid separation software

We can support you to determine and evaluate the centrifuge, best suited to the your needs and production expectations, using the oriented software CENTRISTAR, dedicated to filtration and optimization of the solid/liquid separation process.

CENTRISTAR (www.nikifos.com) permits the calculation and optimization of the performance of a given machine or the design of a new centrifuge, using material parameters by analysing product data sheet, experimental data from laboratory, pilot or industrial tests.

The centrifuge process simulation can calculate the following result parameters: mainly the cycle time, the solids throughput (dry solids mass in the machine divided by the cycle time), the cake moisture content and in case of cake washing the washing liquid flow rate, the washing time and the purity (wash out content) of the discharged cake.

Analysis of Cake Flow Through Tests (FF-Module)

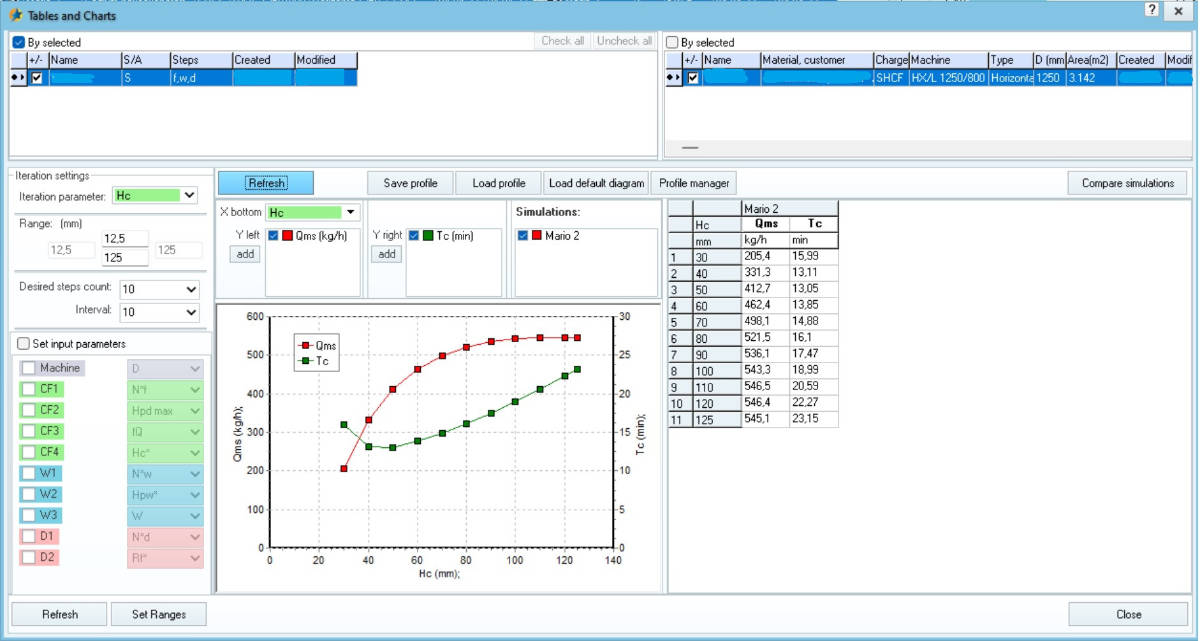

Centrifuge optimization result:Throughput output

Training

Our engineers and technicians are able to provide training of the Customer’s staff for the following aspects:

Use of the centrifuge;

- Optimization of the production process;

- Inspection and maintenance;

- Automation of new processes;

- Update on new safety regulations

We are able to offer a "customized " training for the Customer's needs.

Italiano (it-IT)

Italiano (it-IT)  Español (España)

Español (España)  Deutsch (Deutschland)

Deutsch (Deutschland)  Français (France)

Français (France)