Specification

- High separation efficiency for products with fine particles, compressible (low filterability), fine chemical/API (Active Pharmaceutical Ingredients)

- Gentle handling of the crystals: the solids discharge is achieved by means of the filter cloth inversion. The soft crystals are recovered without breakage

- Due to the short discharging time and the complete elimination of the heel cake at every cycle, it’s possible to work with thin cakes allowing to separate products with low filtering properties (fine particles, high compressibility), achieving a very good/uniform cake washing;

- C.I.P.: very good possibility of achieving an efficient C.I.P. (Clean In Place) thanks to the use of the W.M.E. (Washing Machine Effect) and spray balls

- Capability of pre-drying or even drying (for some products) thanks to the HCS (Hyperbaric Centrifugation System), supplying N2 at max 6 barg into the basket for further dewatering the capillaries inside the cake (reduction of the residual moisture)

- Cake volumes from 7 (pilot unit) to 210 l

- High G factors from 1018 to 1663 (pilot unit)

- Basket load setting via load cell system;

- Even cake due to the horizontal design;

- Filter cloths available of PP of Halar or PTFE;

- Gas tightness at 400 mm H2O;

- Completely inspectable process area thanks to the fully openable front casing;

- Easy installation (isolation from unbalance loads by means of rubber dumpers);

- Through the wall installation;

- No contact between operator and product during operation;

- Electromechanical filter cloth inversion (oil free execution);

- Various levels of containment at solids discharge

- High finish surfaces;

- Complete FDA validation documentation;

- Materials in contact with the product: all stainless steels and special alloys available, such as AISI 316L, AISI 904L, Hastelloy, Monel, ALLOY 59, 254 SMO, NICKEL, TITANIUM, SAF 2205. HALAR coatings (ECTFE), also antistatic and FDA certificated, Teflon ETFE, HARD RUBBER

Technical Data

| Centrifuge model: HT/GMP | Basket diameter | Basket length | Filtering surface | Cake volume | Slurry density | Max load | Max speed | G factor | Centrifuge weight |

|---|---|---|---|---|---|---|---|---|---|

| Unit | mm | mm | m² | dm³ | kg/dm³ | kg | RPM | xg | kg |

| 300/110 | 300 | 110 | 0,1 | 7 | 1,25 | 9 | 3150 | 1663 | 1400 |

| 470/180 | 470 | 180 | 0,27 | 27 | 1,25 | 34 | 2300 | 1390 | 3000 |

| 600/225 | 600 | 225 | 0,45 | 52 | 1,25 | 65 | 2000 | 1340 | 4000 |

| 700/225 | 700 | 225 | 0,52 | 65 | 1,25 | 81 | 1850 | 1338 | 4600 |

| 800/350 | 800 | 350 | 0,90 | 122 | 1,25 | 152 | 1600 | 1144 | 8500 |

| 900/350 | 900 | 350 | 1 | 145 | 1,25 | 181 | 1500 | 1131 | 8700 |

| 1000/430 | 1000 | 430 | 1,35 | 210 | 1,25 | 262 | 1350 | 1018 | 9400 |

Functioning

Production

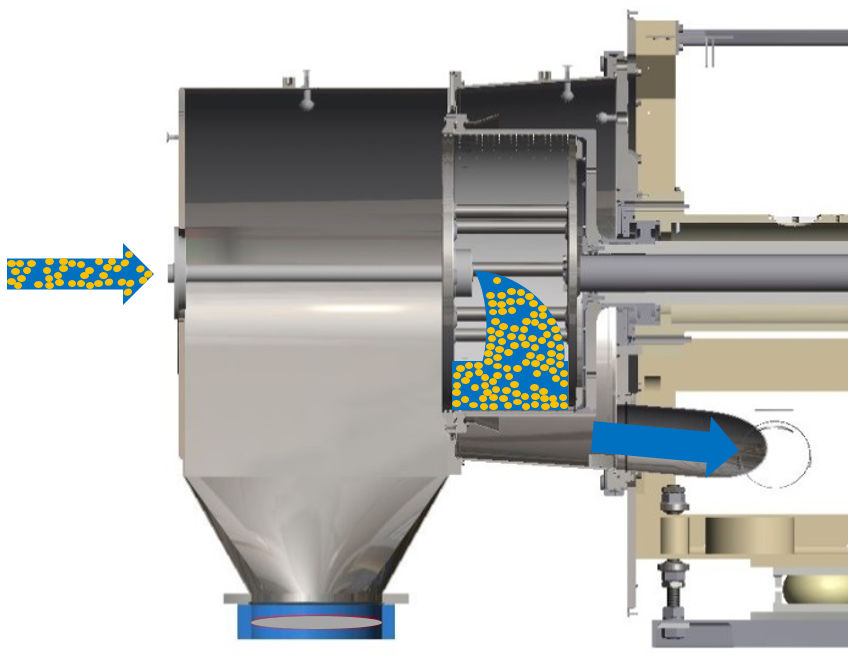

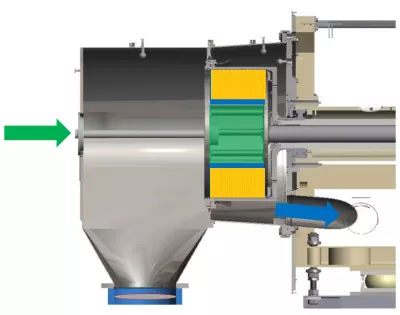

Feeding

The solid-liquid suspension is fed through the feed pipe into the centrifuge and under the action of centrifugal force it moves towards the filter cloth, placed on a perforated basket. The solid part of the suspension is retained by the filter cloth forming a cake, while the liquid filters through the cake and the cloth and is discharged through the holes of the basket. The feed pipe is located at the center of the basket. A loading cell measures the product weight fed to the basket and stops the feeding when the desired weight is reached.

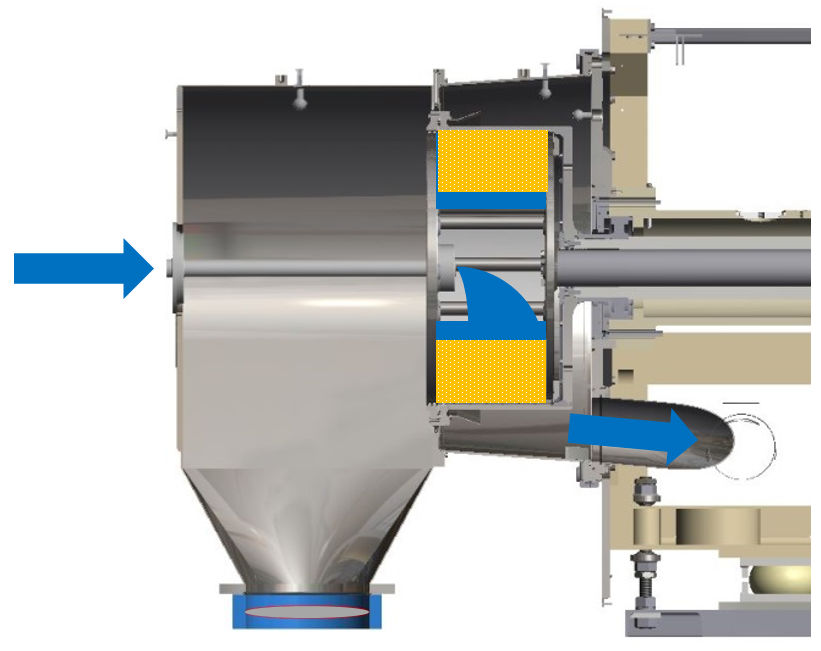

Cake washing

The washing liquid is fed through the feed pipe. The basket internal geometry and the feed pipe position cause a turbolence in the washing liquid and its uniform distribution in the cake

Final deliquoring (Centrifugation)

Once completed the washing phase, the centrifuge is accelerated to the maximum speed and maintained for a given time to achieve the desired level of product residual humidity in the product.

Further deliquoring (with Hyperbaric Centrifugation System – HCS)

If the centrifugal force cannot further deliquor the capillaries inside the cake (poor filtration products), Hyperbaric Centrifugation System (HCS) can reduce residual moisture blowing nitrogen at high pressure (till 6 bar) into the basket. The nitrogen pressure and its flow reduce further the capillary height and the liquid around the product crystals, decreasing the residual moisture. If the nitrogen is also heated up, an additional evaporation effect is achieved

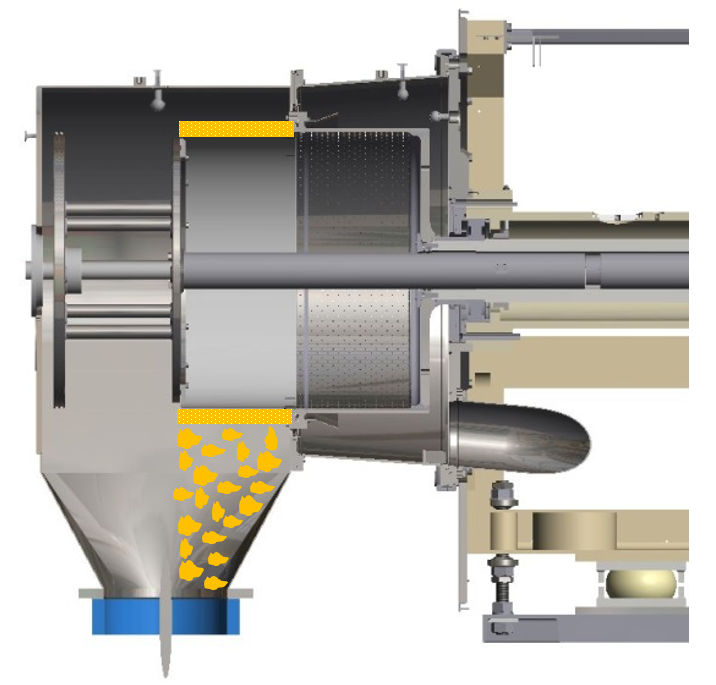

Solid discharge

At the end of the centrifugation, the centrifuge reaches the discharging speed and the product is discharged. The mobile part of the basket is moved to the front part of the machine by means of the axial movement of the inverting shaft. This movement generates the inversion of the filter cloth and the discharge of the product.

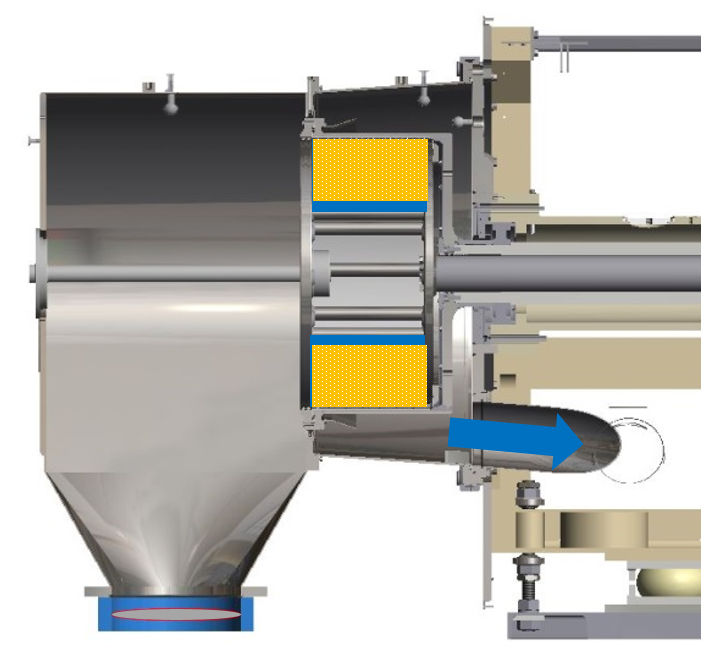

Claen in place (C.I.P.)

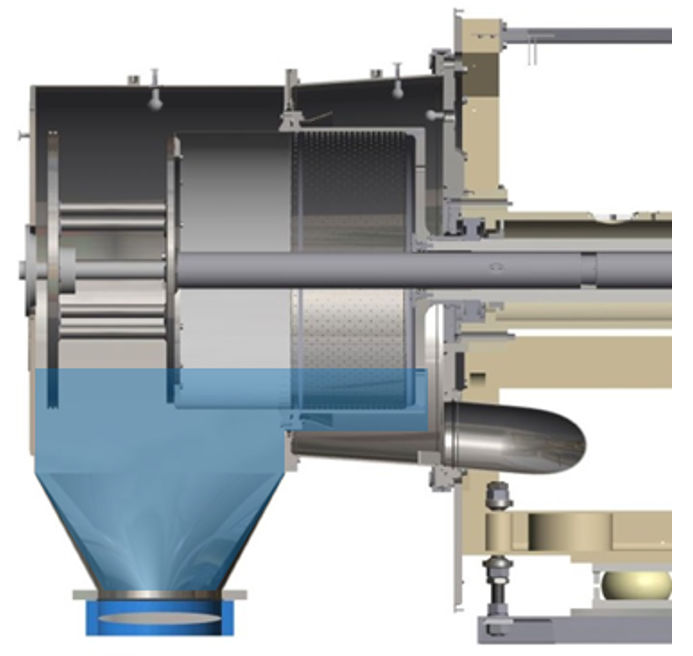

Washing Machine Effect (WME)

The centrifuge is filled with the washing liquid up to a predetermined height and put in rotation. During the sequence, the basket rotates clockwise and counterclockwise. the mobile drum goes in and out so that the washing liquid reaches all the points of the process area.

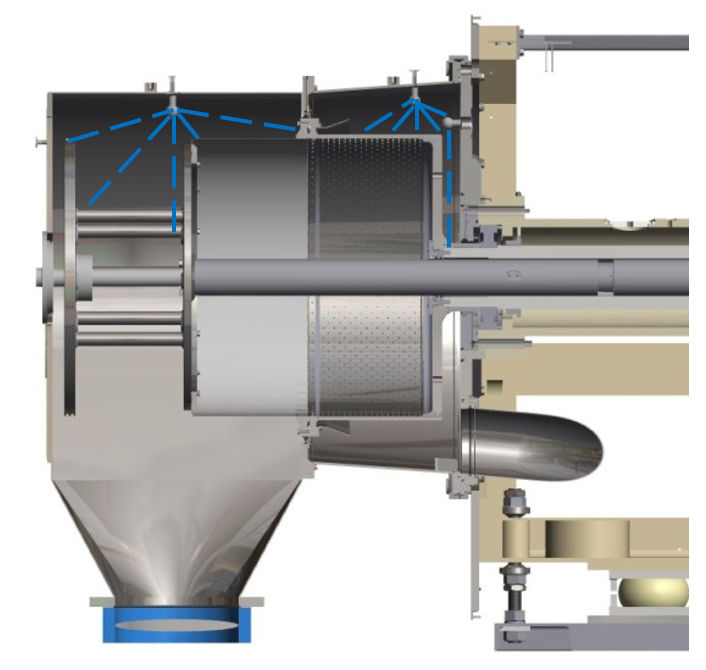

Cleaning with spray balls

The cleaning liquid is sprayed through all the spray balls on all the process area surfaces to completely remove the residues of product still present.

Italiano (it-IT)

Italiano (it-IT)  Español (España)

Español (España)  Deutsch (Deutschland)

Deutsch (Deutschland)  Français (France)

Français (France)