![]()

Offices

![]()

Factory

COMI CONDOR has two plants, one in Settimo Milanese (Milano) and the other in Santa Cristina (Pavia), with a total of around 84 employees

The Settimo Milanese site includes the commercial, administrative, financial, purchasing offices and the mechanical and electronic engineering departments.

The Santa Cristina factory covers some 6000 m2, with a total site area of 25000 m2.

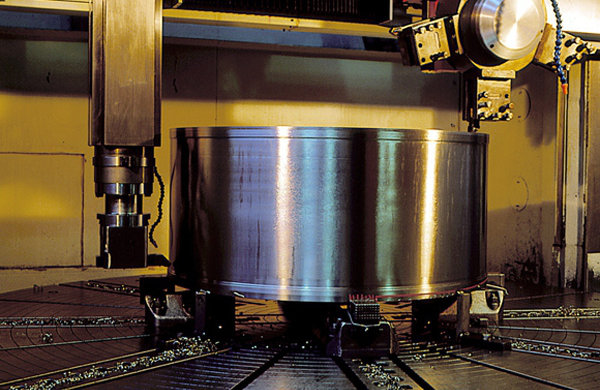

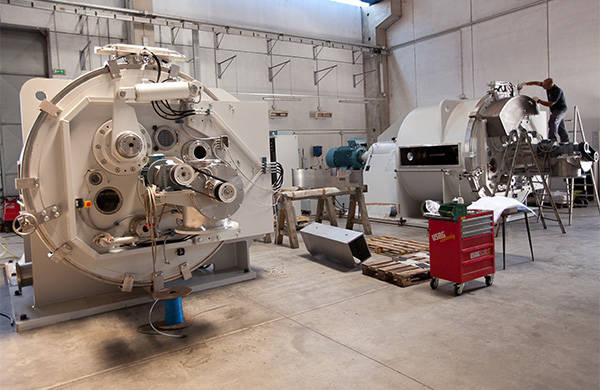

The production site houses all the departments for the production, assembly and testing of the centrifuges.

The modern workshop, consisting of a welding department, cleaning and polishing, water jet cutting, machining department equipped with several CNC machines, allows production of high quality and totally controlled.

The advantages of producing all the parts inside our workshop are:

![]()

Production times control

![]()

Supplies in a short time in case of need

![]()

Quality control*

*Each piece is checked in all the steps of manufacturing; at the end of the production machines are controlled in every detail

**Customer Benefits: One site for inspection, in case of frequent scheduled checks on construction, execution of details, especially for weld checks

COMI CONDOR is one of the companies which produces a complete range of centrifuges. In particular: horizontal axis "peeler", inverting filter, vertical axis bottom discharge, vertical axis top discharge. Currently, the COMI CONDOR machines installed around the world are more than 5000.

The software for the process management is developed and produced completely internally, with the following advantages:

- More flexibility in software development "tailored" for the customer

- Any variants and software updates during the start-up and production, very quick and easy

The company is certified according to the international quality standard ISO 9001-2015 and has the certification for some products according to the ATEX Directive 2014/34/UE

What sets us apart

Our range of industrial centrifuges is the ideal solution for those seeking high performance, reliability, and flexibility.

Quality and precision: Our centrifuges are designed and built with the utmost precision, guaranteeing reliable and reproducible results in every process.

Customization: With years of experience in the sector, we are able to offer customized, innovative, and reliable solutions to meet the specific needs of each customer.

Long life: Our products are built to last, withstanding the most demanding conditions and reducing maintenance costs.

Energy efficiency: Our centrifuges are designed to optimize energy consumption, helping to reduce operating costs and environmental impact.

Regulatory compliance: Our centrifuges comply with the latest international regulations, guaranteeing maximum safety and reliability.

Our actions for a sustainable future

Eco-efficient design

Our products are designed to optimize energy consumption and minimize waste production throughout their lifecycle. We use durable and recyclable materials, prioritizing suppliers who share our values.

Sustainable production

We have implemented production processes that minimize environmental impact, optimizing water and energy consumption and minimizing waste production.

Eco-sustainable logistics

We collaborate with logistics partners who share our sustainability goals, optimizing routes and using low-impact transportation.

Transparency and communication

We believe in transparency and communicate our sustainability results openly, involving all stakeholders.

Our future goals

Further reduce our environmental impact

We are committed to reducing greenhouse gas emissions, water consumption, and waste production.

Promote sustainable innovation

We invest in research and development to develop new technologies and solutions that contribute to a more sustainable future.

Involve our stakeholders

We collaborate with our suppliers, customers, and employees to promote a corporate culture that is increasingly focused on sustainability.

COMI CONDOR is aware that sustainability is an ongoing challenge that requires constant commitment. We believe that through concrete actions and a long-term vision, we can contribute to building a better future for generations to come.

History

The company COMI (COMI CONDOR nowadays) has expanded considerably until reaching the current leading position in the Italian and world markets, in the discontinuous filtering centrifuges’ field, for the pharmaceutical, chemical and food industry.

The COMI company is born

The manufacturing of centrifuges under the name “CONDOR” was started, with the valued contribution of Eng. Giuseppe Poma (previously production manager at "COMI") and Mr. Luigi Cavallotti (co-founder).

The first prototype of a completely hydraulically-controlled centrifuge, particularly suitable for hazardous areas, was produced, followed in 1962 by the “Turbin-Matic” series with bottom discharge

The company COMI CONDOR was established and a new site in Settimo Milanese (MI) is erected.

The new Santa Cristina factory was opened, designed and equipped with modern workshops for the manufacture, construction and assembling of industrial centrifuges of various types.

The production was concentrated on the manufacture of centrifuges, with special emphasis on cleaning and compliance with the cGMP requirements.

The production of centrifuges for starch and chemical applications with baskets over 2 meters diameter was started (the biggest productivity in the world).

Comi Condor, thanks to their constant research and innovative designs, can provide modern/tailor made solutions in the solid/liquid centrifugation field, for customers all over the world. Comi Condor is still a private limited company belonging 100% to the Poma family

Italiano (it-IT)

Italiano (it-IT)  Español (España)

Español (España)  Deutsch (Deutschland)

Deutsch (Deutschland)  Français (France)

Français (France)